APPLICATION AREAS

Electric Power

In the power generation sector, the reliability and precision of measurement instruments directly impact plant safety and operational efficiency. With two decades of specialized expertise, LEEG serves as a trusted measurement solutions provider for power plants, delivering comprehensive instrumentation that enhances safety, efficiency and cost-effectiveness across all plant types.

Critical Applications in Nuclear Power Plants

LEEG instruments play a vital role in nuclear power applications. In reactor cooling systems, high-precision differential pressure transmitters monitor the pressure difference at the main pump's inlet and outlet, ensuring proper coolant circulation. Specially designed high-temperature pressure transmitters, capable of withstanding temperatures up to 400°C, provide reliable pressure monitoring for steam generators. Auxiliary systems, including boric acid solution flow meters and containment vessel level monitors, collectively ensure the safe operation of nuclear power plants. All nuclear-grade products comply with stringent standards such as HAF604, meeting nuclear safety requirements.

Comprehensive Solutions for Thermal Power Plants

LEEG's measurement solutions cover the entire process flow in thermal power plants. In boiler systems, high-temperature and high-pressure transmitters (rated for 25 MPa/600°C) deliver precise pressure data for steam pipelines, while differential pressure water level gauges ensure safe drum water levels. In turbine systems, applications such as lubricating oil flow monitoring and bearing temperature measurement effectively prevent equipment failures. For flue gas treatment, slurry density and pressure monitoring help power plants meet environmental emission standards.

Electric Power

Advancements in Renewable Energy Power Generation

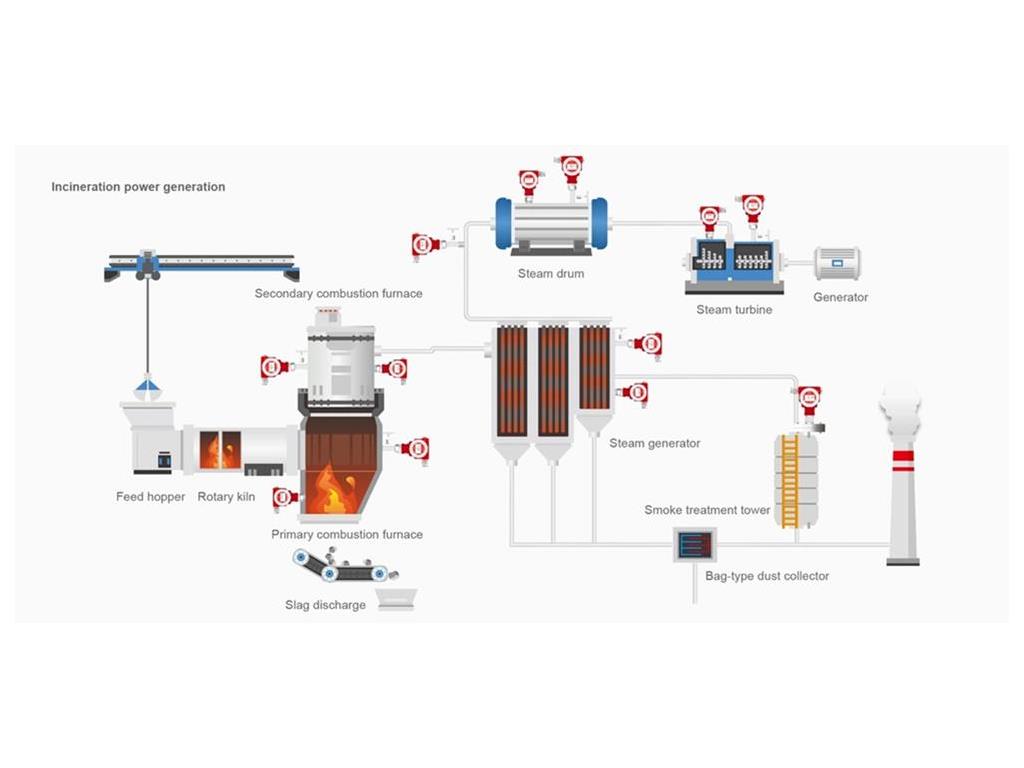

LEEG also demonstrates technological advantages in renewable energy applications. For gas turbines, precise fuel gas flow measurement and intake differential pressure monitoring optimize combustion efficiency. In biomass power plants, material level monitoring in silos resolves feedstock transportation challenges, while pressure control in flue gas treatment systems enhances environmental performance. These applications highlight LEEG's adaptability to demanding operating conditions.

Core Competitive Advantages of LEEG Products

LEEG's strengths are reflected in three key areas:

- Professional Expertise: Products are certified for nuclear and explosion-proof applications, undergoing rigorous testing and validation.

- Smart Capabilities: Support for multiple communication protocols (e.g., HART, Profibus-PA), with self-diagnostic and remote monitoring functions.

- Service Assurance: Full lifecycle technical support and customized solutions.

A case study of a 1000 MW ultra-supercritical unit demonstrated significant improvements after adopting LEEG's solutions, including enhanced boiler efficiency, reduced unplanned downtime, and lower maintenance costs.

Electric Power

Future Outlook

As the power industry moves toward greater efficiency and sustainability, LEEG will continue to innovate in measurement technology, delivering smarter and more reliable solutions for global power customers. We look forward to collaborating with more power enterprises to create greater value through precision measurement.